6 Key Considerations for Choosing an Engine Generator

Engine generators are versatile power sources that support various outdoor applications, including civil engineering, construction, road works, etc. Given their importance and high cost, selecting the right generator requires careful planning and consideration to avoid costly mistakes. In this article, we will walk you through the key points to consider before investing in an engine generator, ensuring you make an informed choice that meets your operational needs.

Understanding Your Power Requirements

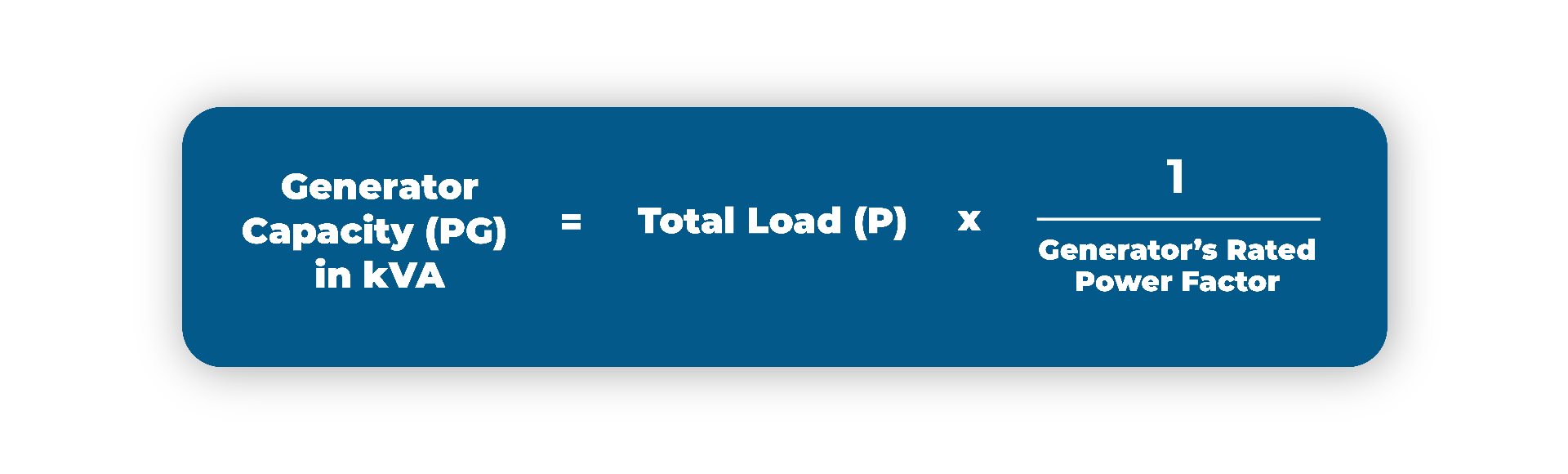

Before selecting a generator, it is essential to determine your power requirements, as this is the primary reason why you need an engine generator in the first place. Ensuring the generator can handle your equipment’s load without risking damage or inefficiency is a crucial factor, not just for immediate needs but also for future demands. An oversized or undersized generator can significantly affect its performance, efficiency, and lifespan. An undersized generator may struggle to meet power demands, leading to continuous overloading, causing overheating and reducing your generator’s longevity. On the other hand, an oversized generator operates below its optimal capacity. While this avoids overloading, running low load consistently can damage the engine over time and lead to fuel inefficiencies.

Hence, ensuring your generator can handle your equipment’s load is important. Read up on How to Calculate and Determine Your Power Requirements for Generators to understand your power demands.

Noise Pollution Control

Noise pollution is an unseen threat that affects both people and wildlife, causing disruptions in everyday activities like sleeping and conversation, ultimately diminishing one’s quality of life. This issue is especially relevant in urban areas where high noise levels can lead to stress and health problems. As awareness of noise pollution grows, there is an increasing demand for quieter solutions, leading to the establishment of regulations for machinery, including diesel generators. Traditional diesel generators are often noisy, contributing significantly to environmental sound pollution. In response, manufacturers have developed silent generators designed to minimize noise output while maintaining efficiency and performance.

Silent generators are equipped with advanced soundproofing technologies, such as acoustic enclosures and noise-dampening materials – significantly reducing operational noise. This helps businesses comply with local noise regulations and creates a more pleasant environment for nearby residents, schools, and hospitals. When choosing a generator, consider your location and the nature of your business. In areas close to residential zones or public facilities, silent generators can help avoid potential disruptions. Moreover, in remote or less populated regions, the reduced noise level can enhance your work environment, making it easier to focus without the constant hum of traditional generators.

In summary, opting for a silent diesel generator contributes to noise pollution control and supports a healthier, more productive atmosphere for your business and the surrounding community. Find out why construction noise is becoming a public concern in Singapore.

Considering Size and Portability When Selecting an Engine Generator

Another critical factor often overlooked when selecting an engine generator is its physical size, which can significantly impact transportation, space requirements, and ease of handling at the worksite. A generator that is too large may require additional transportation means and complicate storage, while a smaller, more compact model can enhance operational efficiency. Choosing a compact and lightweight generator is highly recommended for projects with frequent relocation needs. These models are easier to manoeuvre and reduce the complexity involved in loading and unloading, saving time and resources.

Furthermore, consider opting for a generator with a sturdy, stackable design. Generators designed for double stacking maximize storage space, allowing more efficient use of limited areas, especially on construction sites where space can be a premium. By stacking generators, you can optimize transportation loads and reduce the required trips, leading to cost savings and a more sustainable operation. Check out more on the two-stack type generator solution here.

Environmental Friendliness

In construction and event management industries, the environmental impact of equipment choices is becoming an essential consideration. Engine generators are no exception, as their operation can significantly affect local air quality, soil health, and overall sustainability. By choosing environmentally friendly generator options, businesses support regulatory compliance and demonstrate a commitment to responsible, sustainable practices.

Emission Standards and Compliance

Emission regulations for machinery are stringent in many regions, especially in areas with frequent public activity or sensitive ecosystems. Hence, selecting generators that meet high emission standards, such as Japan's Tier 3 or equivalent, ensures that your operation minimizes harmful pollutants such as nitrogen oxides and particulate matter. For construction sites or event spaces near residential areas, low-emission generators can help reduce health risks associated with poor air quality, fostering a safer, more compliant operation.

Eco Base and Spill Prevention

Generators equipped with an eco-base offer a practical solution for environmental spill prevention. The eco-base acts as a containment system that captures any accidental leaks of fuel, oil and coolant water when discharged accidentally, which is critical on job sites near sensitive natural areas or water bodies. This feature reduces potential soil and water contamination and minimizes costly clean-up efforts associated with environmental spills.

Fuel Efficiency and Carbon Footprint

Fuel efficiency directly affects both operational costs and the carbon footprint of any power generation solution. Features such as common rail enhance combustion efficiency, meaning the generator uses fuel more effectively and produces fewer emissions. Businesses can reduce their carbon impact by choosing fuel-efficient generators, contributing to broader sustainability goals. Environmental friendliness in generator selection ultimately supports long-term operational efficiency and social responsibility. Prioritizing features like emission compliance, spill prevention, and fuel efficiency allows businesses to make a positive environmental impact while meeting the practical demands of their worksite or event location.

Environmental friendliness in generator selection ultimately supports long-term operational efficiency and social responsibility. Prioritizing features like emission compliance, spill prevention, and fuel efficiency allows businesses to make a positive environmental impact while meeting the practical demands of their worksite or event location.

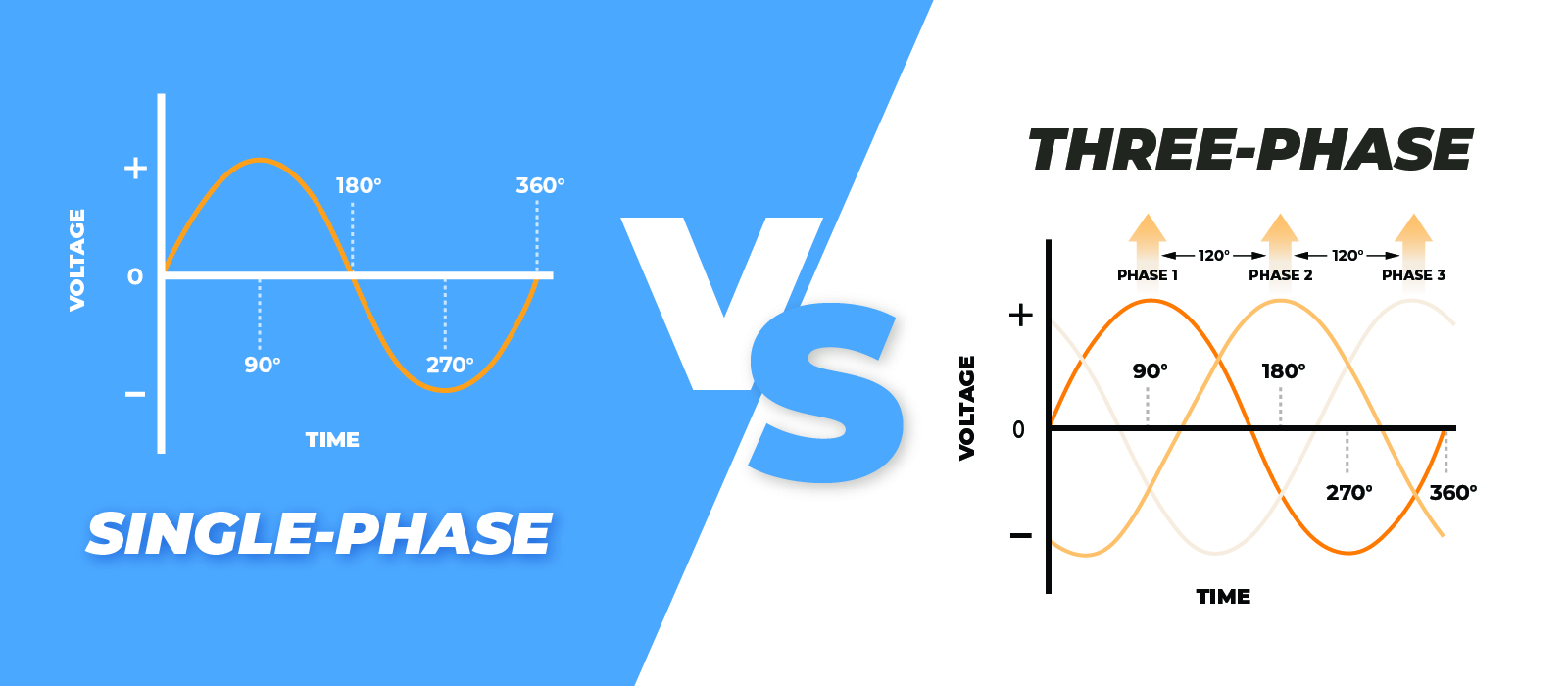

Understanding the Differences between Single-phase and Three-phase

When selecting an engine generator, it is essential to understand the difference between a single-phase and three-phase configuration, as this can potentially affect cost, efficiency, and application suitability. The key difference between both configurations is their power delivery; a single-phase generator delivers power in a single-sine wave and usually provides power at around 190 volts and 220 volts. On the other hand, a three-phase generator delivers power in three sine waves that are 120 degrees out of phase with each other, providing power at around 380 volts and 440 volts.

A single-phase generator is commonly used for smaller-scale applications such as lights, computers, or fans. In contrast, three-phase generators typically power large applications, accommodating larger loads such as air compressors or industrial water pumps due to their constant and stable power flow. For instance, if you require an engine generator to power your construction equipment, a three-phase generator will be more efficient than a single-phase generator. Learn more about the differences between these two configurations here.

After-Sales Service

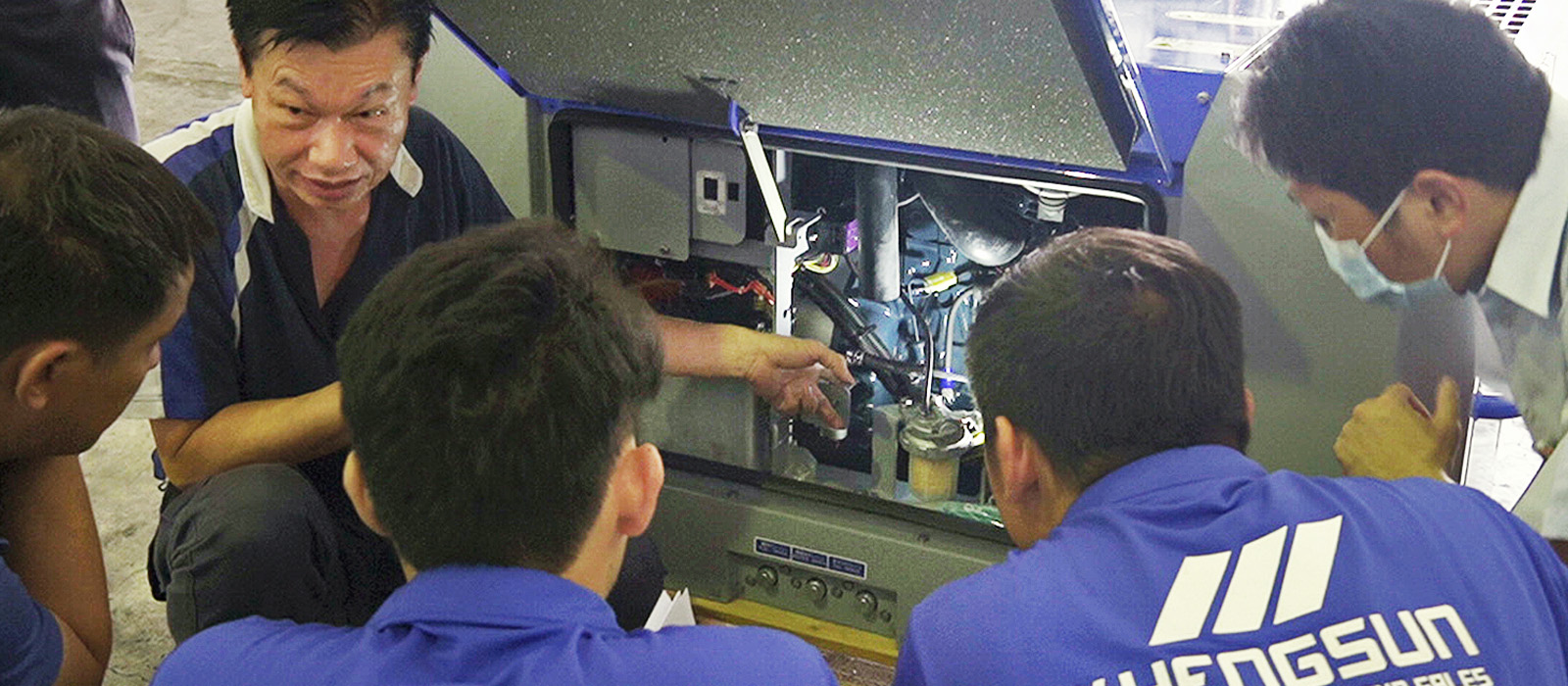

A significant loss can occur to the business if an engine generator breaks down at a worksite. Operations may come to a standstill, leading to delays, increased costs, and idle employees. Therefore, selecting a generator from a manufacturer that offers quick and reliable after-sales service, including a prompt supply of spare parts, troubleshooting, and repairs, is crucial. This benefit becomes even more valuable if the manufacturer has a broad global service network, ensuring after-sales support is easily accessible worldwide. Unforeseen circumstances can arise during generator operation, so choosing a supplier with comprehensive backing minimizes downtime and ensures seamless operations.

Key Takeaways for Selecting an Engine Generator

Selecting an engine generator requires careful planning and thoughtful consideration, as it is a long-term investment that could serve you for the next decade or more. Rather than viewing it as just another piece of equipment, consider it a crucial investment in your operation's reliability and efficiency. Choosing the right generator can ensure uninterrupted power supply, reduce operational costs, and enhance productivity over time. Therefore, understanding your power requirements, site conditions, environmental friendliness, and maintenance requirements is essential to making the right choice.

Denyo takes pride in its products, constantly innovating and providing additional customer support. Denyo has pioneered a series of silent generators, ranging from "Ultra Silent Type" to "Soundless Type". With an expansive global service network, Denyo made after-sales service easily accessible for customers from all around the globe. Do reach out to us if you need assistance selecting an engine generator for your operation, project, or worksite.