How to Calculate and Determine Your Power Requirements for Generators

Determining your power requirement is critical when selecting the right generator for your power needs. Whether you plan to use a generator for a construction project or an outdoor event, understanding your power requirement will ensure you choose a generator that can handle the load without risking damage or inefficiency. This article will walk you through the process of determining your power requirements for generators – by understanding the difference between running and starting wattage, calculating the appropriate power factor for your generator, and accounting for potential future power demands.

Understand the Basics: Running vs. Starting Watts

To begin, it is important to understand the difference between running (or continuous) power and starting (or surge) power:

- •Running Watts: This is the continuous running power your equipment, tools or appliances require to keep running.

- •Starting Watts: This is the extra power required to start up specific equipment or appliances, especially those with inductive loads such as electric motors, compressors, pumps, etc. The starting power is typically higher than the running power to account for surge or in-rush current, preventing generator overload

Calculate your Generator Configuration’s Power Factor

Understanding the difference between single-phase and three-phase generator configurations is crucial, as this distinction significantly impacts various aspects of your operations, including efficiency, cost, and suitability for specific applications. Each configuration has its method for determining the generator's capacity, which is essential for ensuring your equipment runs efficiently.

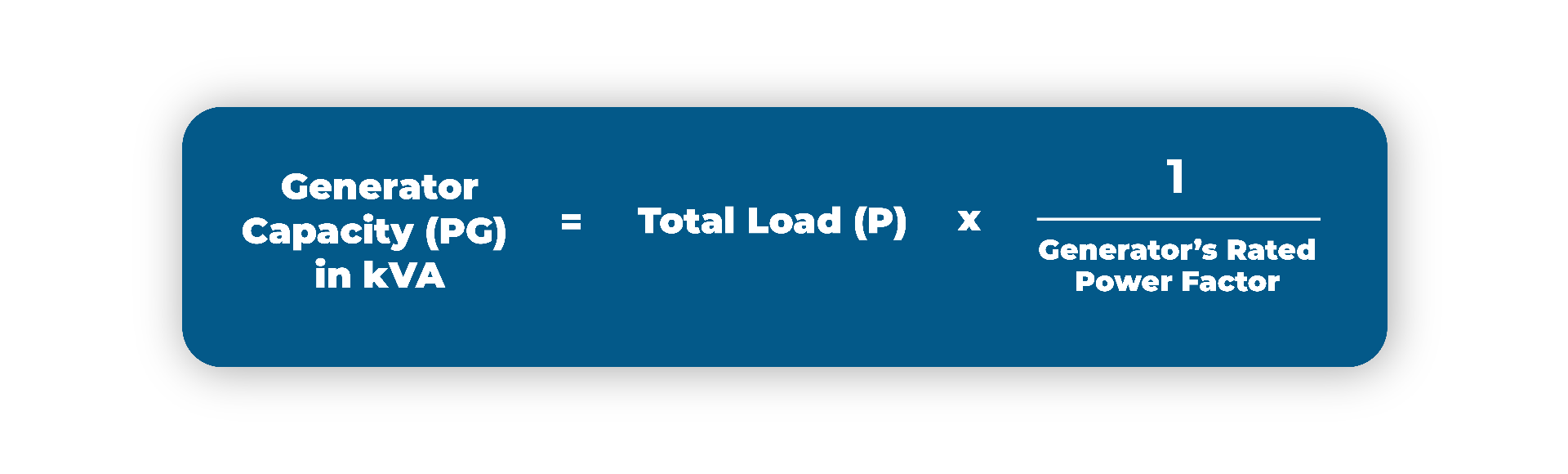

The formula for calculating generator capacity differs between single-phase and three-phase systems, as shown below:

- •Generator’s Rated Power Factor for Single-Phase = 1.0

- •Generator’s Rated Power Factor for Three-Phase = 0.8

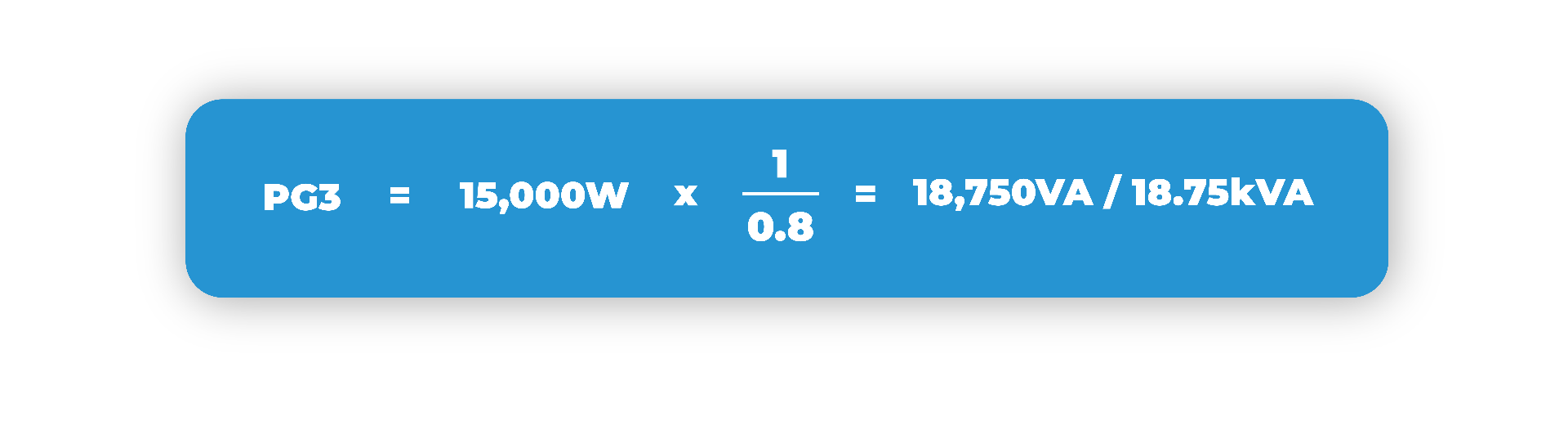

For example, if you require a power crane of 15,000W using a three-phase generator (PG3), the calculation would be as follows:

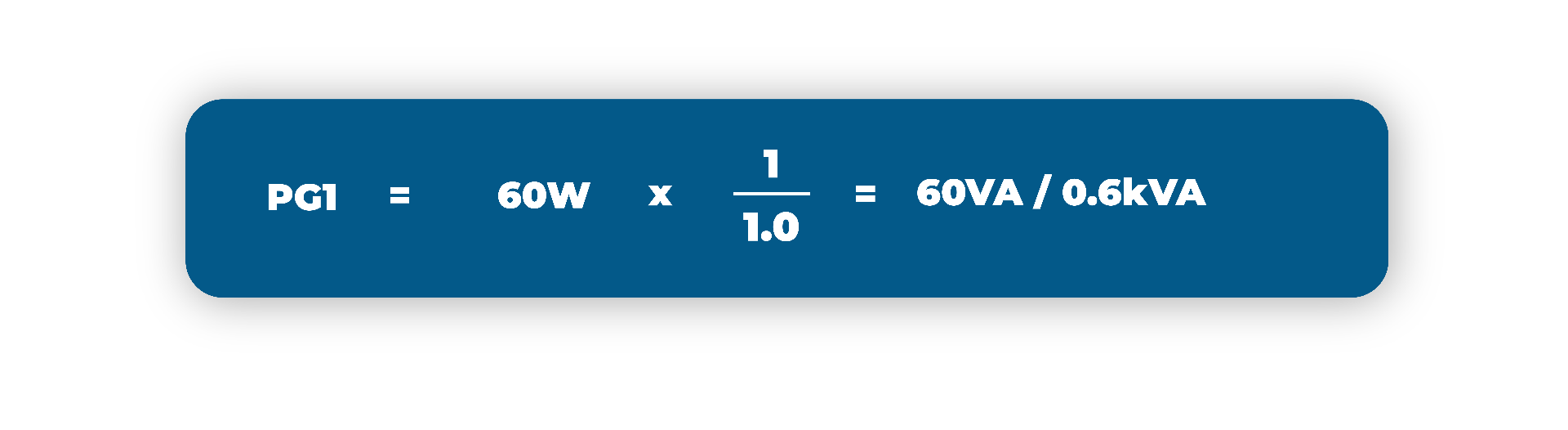

Alternatively, if you need one incandescent lamp of 60W using a single-phase generator (PG1), the calculation would be:

*Disclaimer: Depending on the generator's design and the characteristics of the load it is supplied, different generators and loads will have different power factors. Hence, it is important to note that the provided power factor values are just references to give a better understanding. Users are recommended to check the specific power factor of their generator and loads to ensure accurate performance and compatibility with their equipment.

Ensuring that you choose a generator with the right power factor and configuration allows you to benefit from minimized downtime and smooth operations. To dive deeper into the Key Differences Between Single-Phase and Three-Phase Generator Configurations, click here

Determine the Wattage of Each Appliance

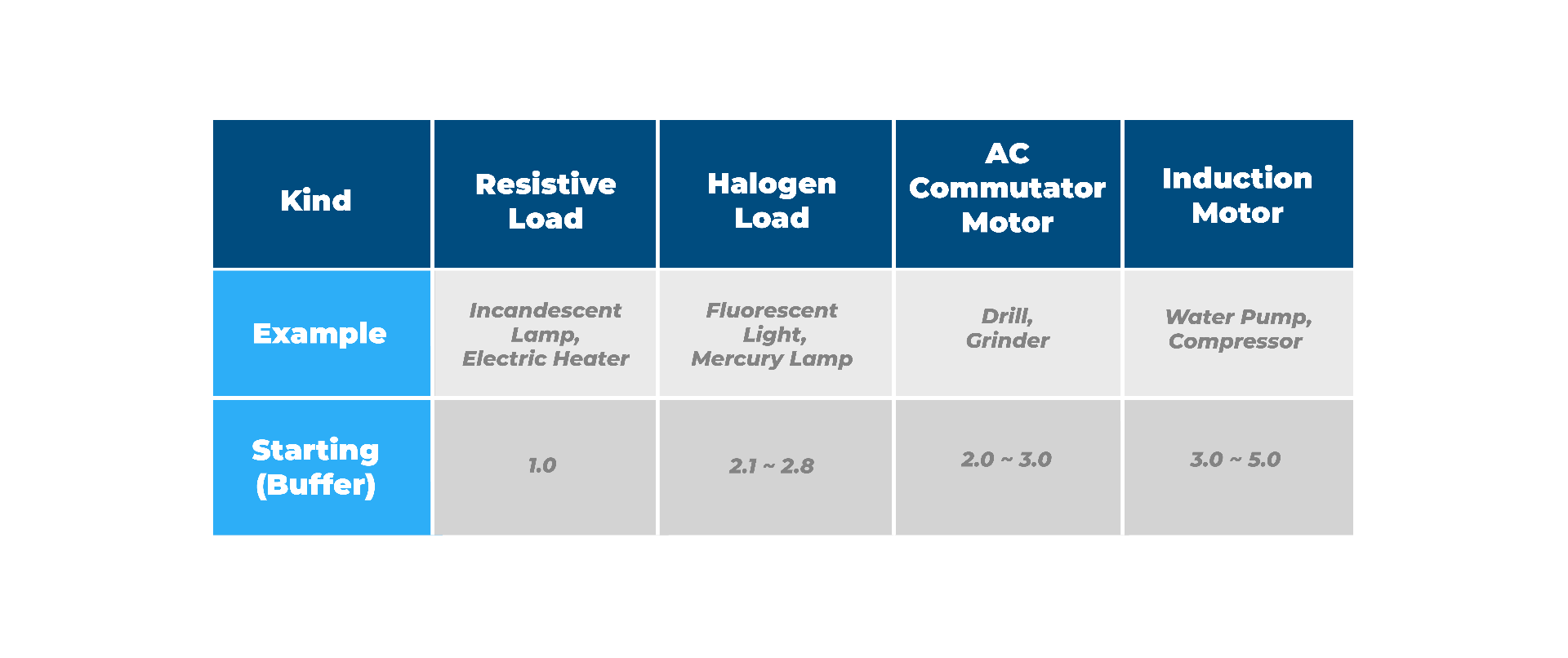

Once you have your equipment list, determine the wattage required for each piece. This information is commonly found on the appliance’s nameplate or user manual. Take a look at the examples below:

To ensure that your generator can handle power fluctuations and avoid overloading, adding a buffer to your total power requirement is recommended. The graph above shows that a start-up buffer of 3.0 ~ 5.0 and a running buffer of 1.3 ~ 2.0 is required for Industrial Motor. This buffer accounts for unexpected surges and ensures that the generator is not constantly running at full capacity, which can lead to quicker wear and tear.

Calculate Total Running and Starting Watts

For instance, if you require to power a power crane of 15,000W and an industrial mixer of 7,500W, how much generator power capacity is needed for this?

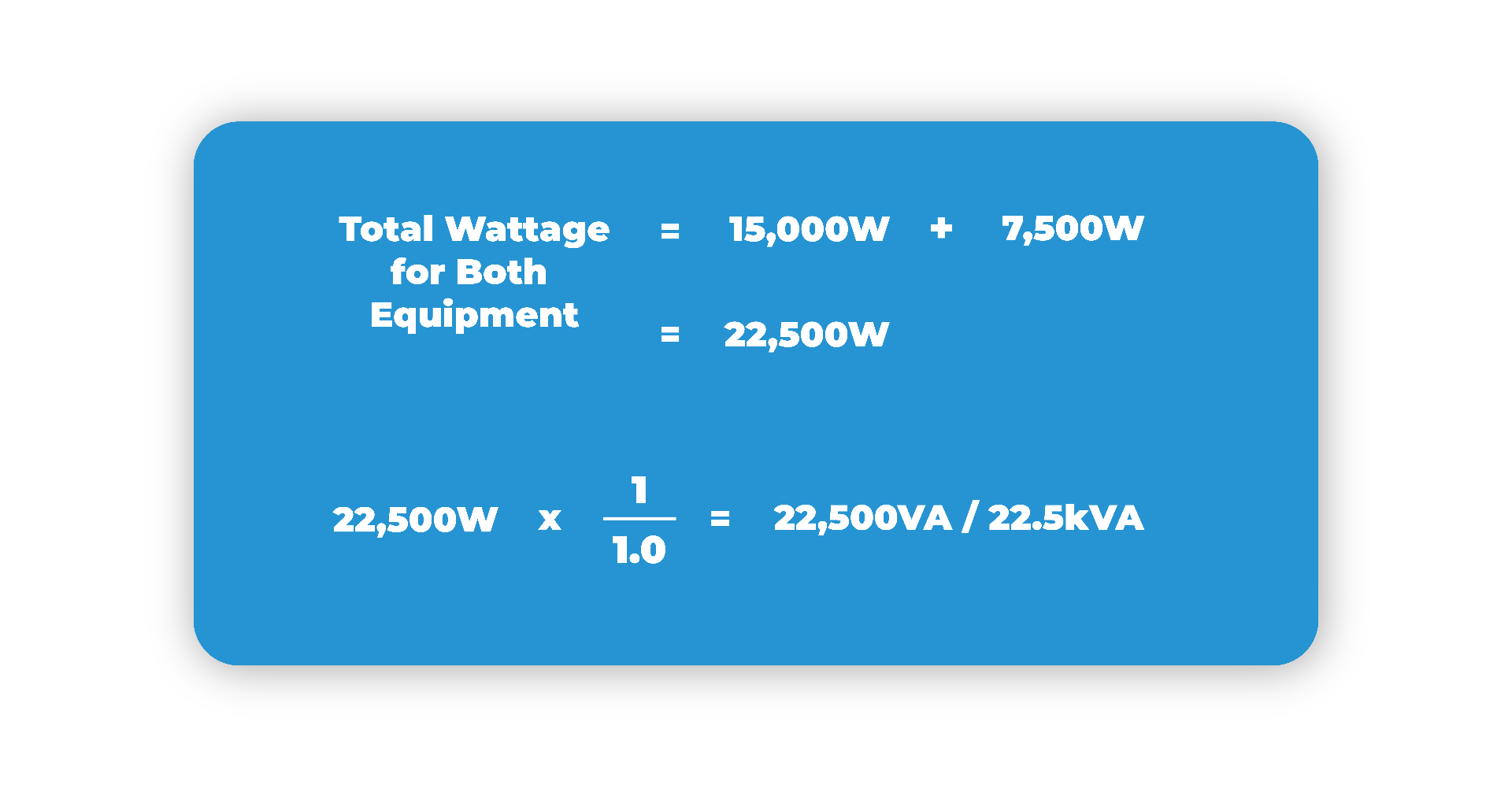

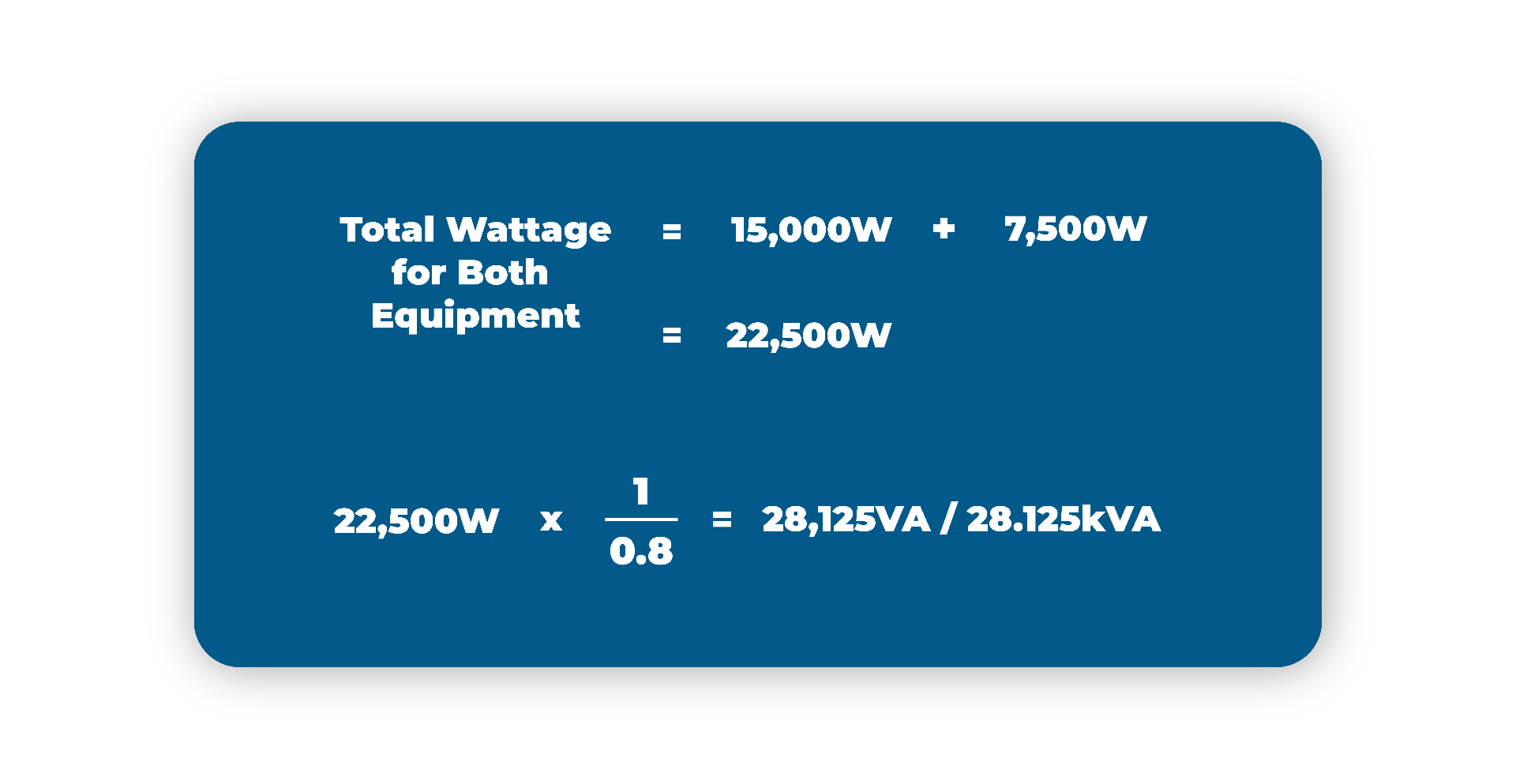

Running (Single-Phase):

Running (Three-Phase):

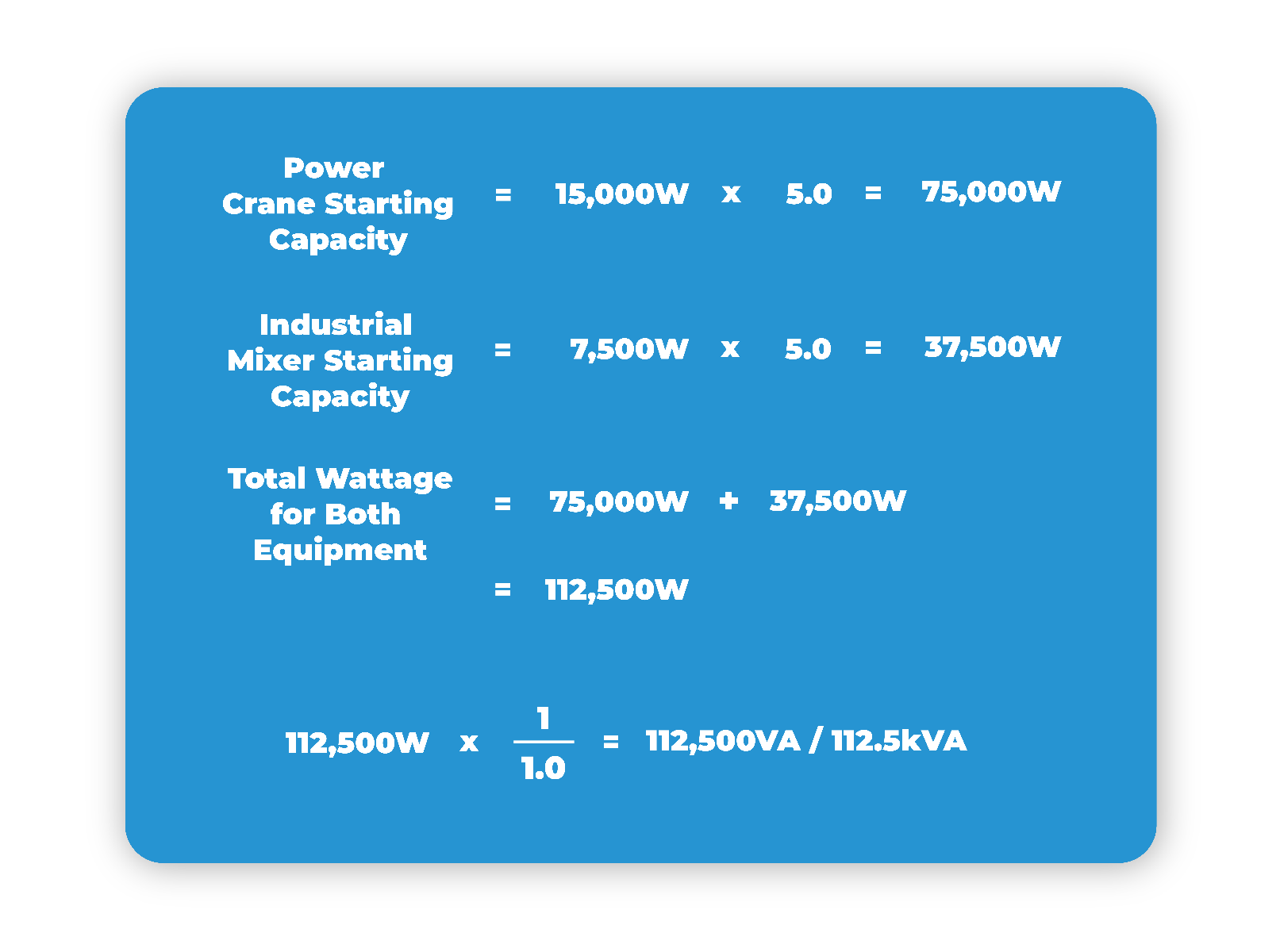

Start-Up (Single-Phase):

Start-Up (Three-Phase):

*Disclaimer: The multiplier of 5.0 is a rough figure provided for this example. To determine the start-up power more accurately, it is necessary to consider motor efficiency, power factor, start-up current, and how the motor is started.

To ensure that your generator can handle peak loads, it is important always to consider the highest power requirement when choosing a generator. If you select a generator with a rated power lower than the power needed to start a motor, the generator will have an overload issue and might not start at all. In this case, you should consider a generator with a minimum capacity of 113kVA (single-phase) or 141kVA (three-phase).

Account for Future Needs

When selecting a generator, it is crucial to consider your current power requirements and anticipate future needs. As your operations grow, your power demands are likely to increase. This might be due to the addition of new equipment, potential expansion, or increased usage over time. By selecting a generator with a slightly higher capacity than your current needs, you can build in a buffer to accommodate these future demands.

This foresight can save you from frequent power upgrades or replacements as your power requirements evolve. Consider factors like planned expansion, new machinery, or shifts in operational hours that could affect your energy consumption.

Additionally, you can discuss this with the engineer of your work site. Usually, an experienced engineer will submit a distribution box that indicates the loads and additional allocation for future machinery. In this case, you can consider a generator that can power the current machinery and allocate additional space for future machinery.

Conclusion

Determining your power requirements is essential for selecting the right generator to meet your needs efficiently and reliably. By understanding the difference between running and starting wattage, calculating the appropriate power factor for your generator, and accounting for potential future power demands, you can ensure that your chosen generator is well-suited to handle current and anticipated loads. This careful planning will enhance operational efficiency and prevent potential overloading, ensuring your generator performs optimally in any situation. By assessing your power needs thoroughly, you can invest in a generator that provides dependable power for all your critical applications.

If you need help calculating your power needs or selecting the right generator, Denyo is here to help. Our team of experts is ready to assist you in determining the perfect generator to match your specific requirements. Do not hesitate to reach out to us for personalized advice and solutions that will ensure the most reliable and efficient power supply for your project. Contact us today to get started!