Do You Know… the Benefits of a Dual-Operator Welding Set?

It is critical for companies to complete jobs on schedule and within budget, in compliance with legal and government regulations on noise and exhaust emissions, amongst other things. Therefore, machinery nowadays have to play a part in all these.

This is where a welder with dual-operator capabilities be part of the solution in meeting these demands. Each welder provides sufficient welding and generator power to meet work demands on-site while offering a number of benefits associated with having dual welding outputs in one machine.

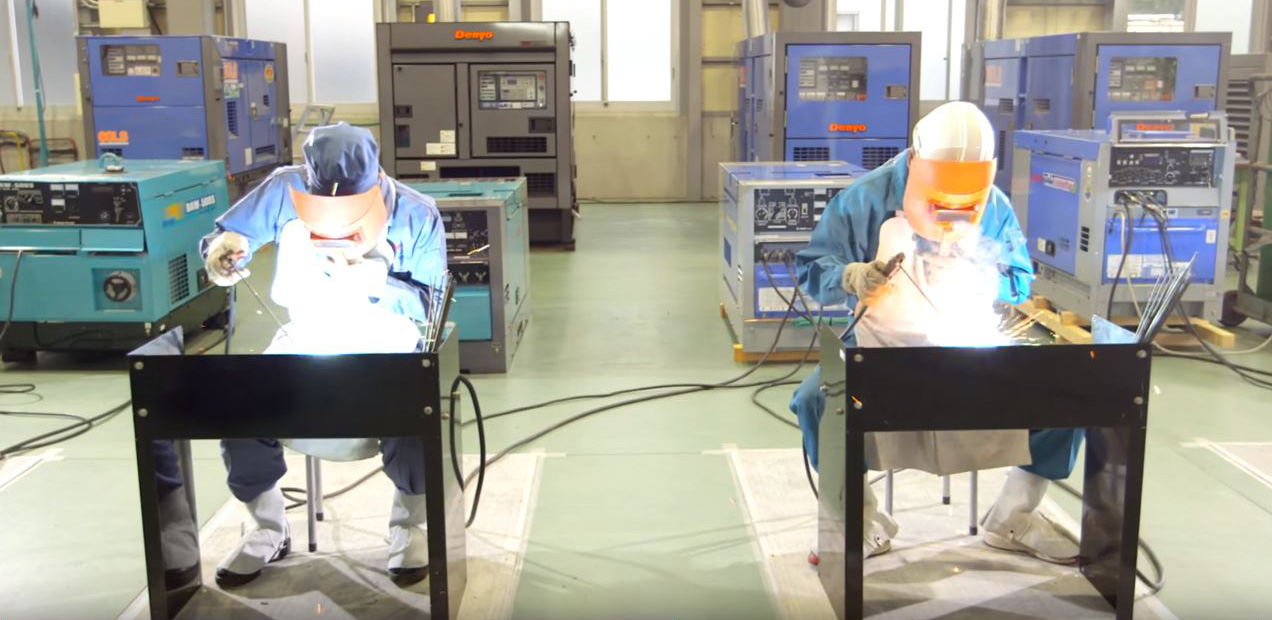

Improved productivity by doubling the welding output of a single machine

Welders with dual-operator capabilities provide enough power not only for dual welding, but to power other tools. This boosts productivity without the cost of adding machines or renting / purchasing generators.

Dual-operating welders maximise resources in the field through two independent weld outputs, making the machine much more efficient — operating at a higher frequency so that the arc noise from one weld output does not affect the output of the other.

Less equipment to transport and move around a site

A dual-welding set is handy. One does not have to set up and move many times during the day or week, and to carry many welders around. He also does not need much transport and its associated arrangements which is easier and faster to reach places and deploy at a faster time.

Lower total cost of ownership than two separate machines

A dual-operator system offers lower capital investment, reduces overhead and associated maintenance costs, and can retain higher resale value.

The ability to reduce the amount of equipment on a jobsite or work truck — while maintaining or increasing productivity - requires less oil changes and routine maintenance when compared to having multiple single-operator machines, and with less equipment equates to reduced maintenance and logistical costs, as well as less clutter, which promotes efficiency and also improves jobsite safety.

Reduced noise reduction and emissions compared to multiple units

Operating multiple single-welding machines creates a noisier jobsite. It becomes worse when one gets into populated areas – not only the welding technician sitting there welding has to suffer the agony of listening to more noise, the people in the area suffer as well – through getting disturbed by the sounds emitted by numerous welders. Therefore, a dual-welding set can improve worker comfort, productivity and safety by having fewer machines and thus less noise created.

In addition, multiple welding sets burn through fuel more quickly and increase the amount of exhaust emissions, polluting the air and causes health problems. A single dual-welding set can significantly reduce this problem.

Taking all of these factors into consideration, a dual-operator welding set is definitely an excellent addition to your equipment list, especially for larger projects. Denyo has a number of welding sets that allows dual-welding and boasts of fuss-free maintenance and clean engine endorsed by the Ministry of Land, Infrastructure, Transport and Tourism in Japan.

Check out our range of Denyo Welders