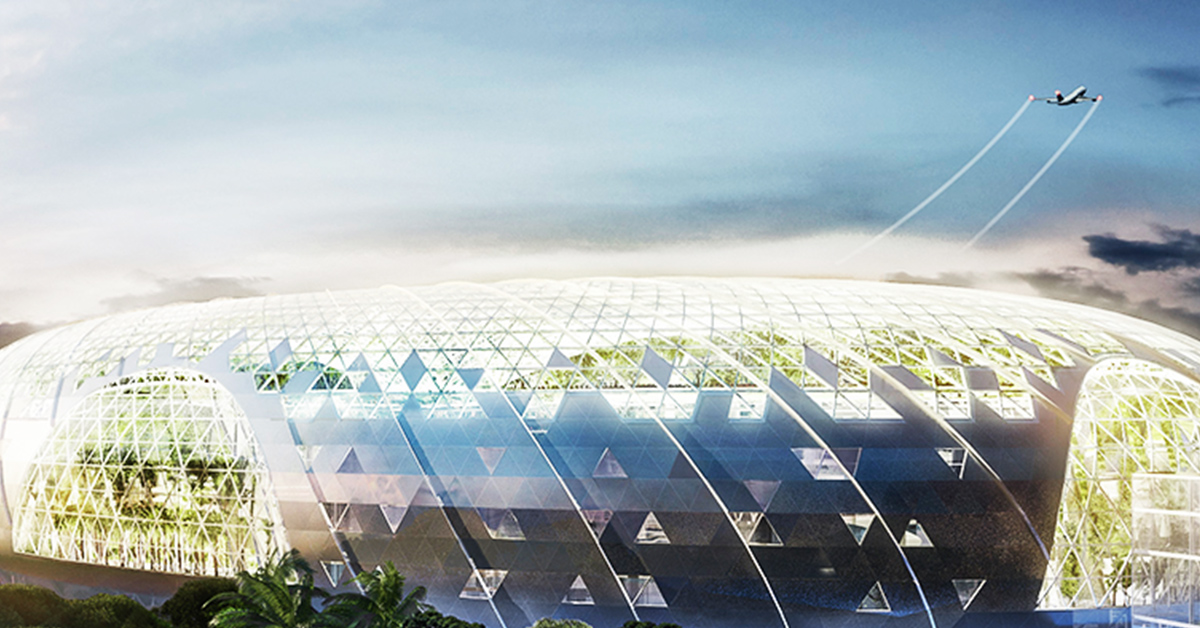

Jewel Changi Airport, Singapore

The Challenge

Singapore’s Changi Airport is a world-renowned landmark and has been synonymous with the island nation’s prosperous development and growth over the decades, garnering countless critical accolades year on year.

A large part of the airport’s success lies in the Singapore Government’s relentless pursuit of excellence, taking every opportunity available to improve and innovate, and Jewel Changi Airport is but the latest of such initiatives strategically designed to ensure that the airport and by extension the Nation stays ahead of the game.

As this is a significant national project, it receives a lot of attention and heavy scrutiny from many stakeholders. No incidents can be allowed to derail the schedule of the development work. Unfortunately, as it transpired, a few breaker tripping incidents were reported onsite which halted work and created frustration for the operations. The root cause of the incidents must be found so as to eliminate the problem and not further jeopardise work progress.

The Denyo Solution

Personnel from Denyo Singapore were sent to the project site on two (2) occasions to assess the situation and conduct further investigation. Detailed reports were generated by the technical team to confirm the root cause of the problem.

In addition, SmartRMS was activated to record readings from the generators at regular intervals to give better insights into the performance the generators throughout the installation period.

In view of the seriousness of the problem, a generator was hauled back to Denyo’s workshop for a complete diagnostic test. After four (4) full days, the generator passed all tests, which led the Denyo technical team to conclude that the culprit of the problem was the poor grounding or insulation of the loads used at the site.

Once the problem has been identified and confirmed, the Denyo team immediately sprang into action, coming up with a new robust design that is suited for sensitive loads used onsite, complete with a re-programming of the generator’s controller and control circuit before sending it back to the project site.

Results

Due to the innovative use of remote monitoring on the generators to register readings from all the tripping incidents, Denyo was able to quickly identify the root cause of the problem and came up with an effective solution to eliminating it.

After the re-programming and circuit enhancement were done, no further tripping incidents were reported. Thus, the project was put back on schedule without any failure.

Product(s) used in this project