Proper Room Ventilation for Indoor Generator Operation

Ventilation may be a simple process of replacing the air in spaces – but in the context of indoor generator setup, it is utmost crucial for optimal performance and safety.

Why? Because generator needs to breathe and inadequate ventilation with poor air movement indoor could potentially lead to unforeseen system failure when the engine combusts and heat-dissipating into the surrounding area. Here are some facts and considerations you should know:

Risk of Inappropriate Room Ventilation

Generators require ample amounts of air to cool and support the engine combustion process by expelling heat generated during operation. While proper ventilation factors in considerations of air movement; it directly impacts the effectiveness of heat removal from within the room.

Therefore failure to meet the requirements will retain heat in the surrounding and overheat the engine – compromising the integrity of the engine seals and causing damage to the head gasket due to metal expansion and pressure from the heat.

Potential Losses to the Organisation

If generator failure occurred due to negligence of appropriate room ventilation, you will have to deal with the loss of power which could mean losses associated with downtime. Even a brief disruption in the electrical power supply can be costly. Therefore, generators are critical for business continuity – offering the ability to assume electrical load during an outage.

Overheating can also shorten the operational life of your generator, meaning you have to spend a significant amount of money to service or replace it sooner than you had intended.

Recommended Indoor Generator Setup

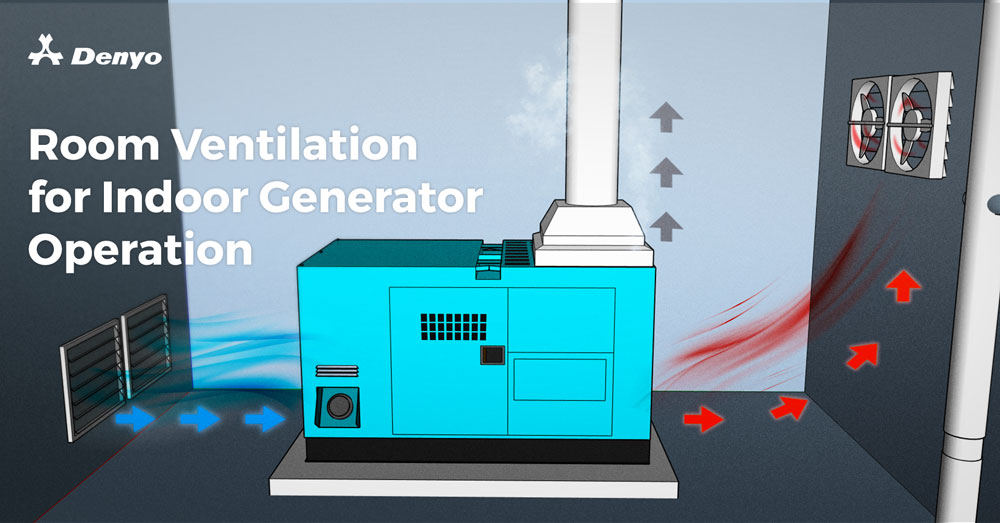

Generators that are installed indoors require careful attention to a multitude of factors – including the accessibility of generators, as well as design and routing of the ventilation airflow.

Accessibility: It is advised to arrange an ample space between the generator and walls of the room – for ease of inspection and maintenance. This way, operators can perform their duties in an efficient and orderly manner – avoiding collision and injuries.

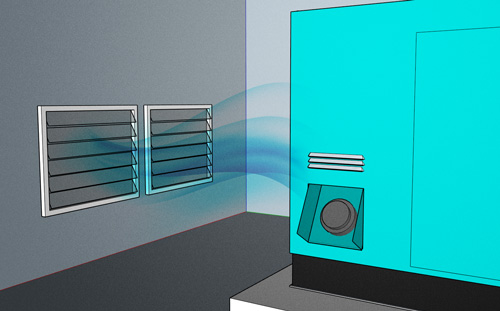

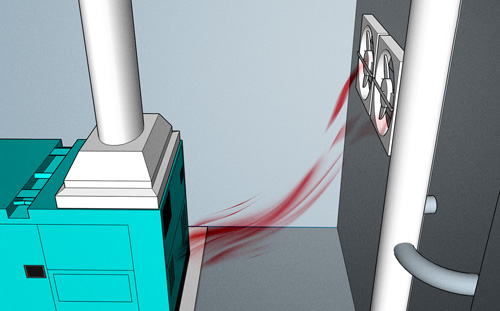

Routing: The source of ventilation air should have a distant entry with the intake louvers positioned as low as possible. The air should flow over the entire generator horizontally, thereby cooling the alternator and effectively purging internal heat. As for the exhaust fans, they should be placed high and directly above the generator to extract heat and undesirable emissions.

Air Duct: Duct systems are likely to require multiple turns. It is optimal to have a curvature design over a sharp radius design (e.g. 90-degree bends) because more energy is needed to push air through sharp bends – which could reduce air-flow and increase the risk of leakage.

If curvature design is not feasible due to space limitations, it is recommended to orient the duct systems and configure the shape with softer bends (e.g. 45-degree bends) that would reduce the restrictions on air-flow.

Work with the Right Generator Provider

As this article explains, ignorance in generator room ventilation could lead to implications that can be potentially catastrophic. As such, choosing the right generator provider that can provide such insights based on your room size, space limitations and mounting capabilities is key consideration strictly not to be overlooked.

At Denyo, we do not just sell you generators. We listen and offer advice on critical parameters to ensure optimal and reliable operation of your generator set – as well as solutions to strive for zero power failure. If you have any upcoming projects and are unsure of your site conditions, we welcome you to contact us for a non-obligatory discussion.