4 Symptoms that indicate your Generator’s Diesel Engine Needs Overhauling

If an alternator is the soul of the generator, then the diesel engine is the heart that keeps the generator going. Constant monitoring and maintenance will avoid dire situations such as machine failure and operational downtime.

When the diesel engine begins to lose power or efficiency, there are many different factors causing detriment. It is crucial to address these issues before they worsen and lead to complete engine failure. In certain circumstances, engine overhauling is the best way to address a problematic diesel engine as it can effectively fix issues with the diesel engine and save you significant amount of money over having it replaced.

It would be beneficial to understand and recognise the signs. As a rule of thumb, an overhauling is vital when the diesel engine exhibits any of the following symptoms:

Increased blow-by gas

Blow-by gas happens when there is a leakage of combustion gases between a piston and the cylinder wall into the crankcase. Measure the flow rate of the blow-by gas and make a judgement. For the measuring method and judgement criteria, do refer to the engine manufacturer’s maintenance instructions.

| CAUSE OF INCREASED BLOW-BY GAS |

|---|

| Worn piston rings and/or cylinder liners |

| Worn valve stems and/or valve guides |

| Clogged breather |

| Abnormal combustion |

| Clogged PCV (Oil separator) |

| Clogged air cleaner |

Increased engine oil consumption

The engine oil consumption may vary depending on the usage environment, oil type or operating conditions. For generator, the oil consumption should be checked against its ratio to fuel consumption.

| CAUSE OF INCREASED OIL CONSUMPTION | OBSERVABLE SIGN |

|---|---|

| Oil leakage due to a faulty oil seal, gasket, etc. | Oil leakage to the outside of the engine |

| Damaged oil cooler | Oil mixed in cooling water |

| Worn or broken oil ring | Reduced compression pressure |

| Worn cylinder liner(s) | Increased blow-by gas |

| Worn valve guides and/or valve stems |

Reduced compression pressure

Diesel engine with low compression pressure may encounter poor startability; therefore it is advisable to determine the root of cause by measuring the compression pressure.

How to measure compression pressure:

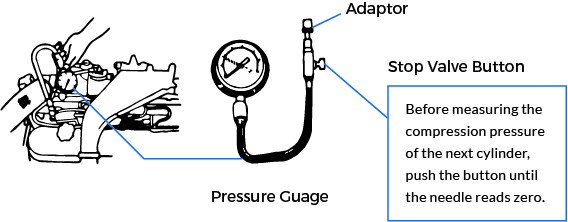

1) Remove the nozzle holder and connect a pressure gauge fitted with a dedicated adaptor in its place.

2) Start the engine with the starter and run it at the specific idle speed to ensure that the compression pressure falls within the specified value.

| CAUSE OF REDUCED COMPRESSION PRESSURE | OBSERVABLE SIGN |

|---|---|

| Worn piston rings and/or cylinder liners | Excessive engine oil consumption |

| Improper contact between the valve and the valve seat | Abnormal exhaust smoke color |

| Poor startability | |

| Premature degradation of engine oil |

Insufficient engine output

There are several causes that could attribute to the abnormal loss in output from the diesel engine. Probable causes include the following:

| CAUSE OF INSUFFICIENT ENGINE OUTPUT | OBSERVABLE SIGN |

|---|---|

| Oil leakage due to a faulty oil seal, gasket, etc. | Oil leakage to the outside of the engine |

| Damaged oil cooler | Oil mixed in cooling water |

| Worn or broken oil ring | Reduced compression pressure |

| Worn cylinder liner(s) | Increased blow-by gas |

| Worn valve guides and/or valve stems | |

| Fuel pump failure | Black smoke emit from the engine |

| Clogged injection nozzles | |

| Improperly timed fuel injection | |

| Turbocharger seizure |

In this article, we have identified the different fault diagnosis method for a diesel engine and probable causes of the symptom. If you have more questions regarding machine servicing, do not hesitate to contact us and our technical specialist.